3D Scanning for Aerospace

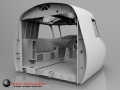

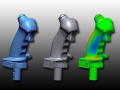

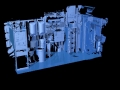

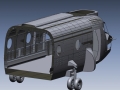

EMS has been providing companies in the commercial and military Aerospace industry with a full range of 3D scanning and precision measurement technologies, as well as on and off-site metrology services for almost two decades. The Aerospace industry presents unique and complex challenges for inspection and space claim measurement needs. Aircraft typically include highly complex assemblies of mechanical parts, electronics, hydraulics, pneumatics and more. Parts and assemblies can be very large and involve tight tolerances, complex designs and FAA certification.Whether the customer's goal is purchase their own 3d scanning equipment or hire EMS for onsite or offsite services, EMS works with the customer to identify the best 3D scanning technologies, software or services that solve the measurement need. EMS offers the 3D scanning technologies and experience to successfuly inspect very small precision components all the way up to 3D scanning and CAD modeling large aircraft interiors and exteriors.

As a product and services provider, EMS has firsthand experience working with the 3D scanning technologies, inspection software and product design tools we represent. From components to small and large aircraft, EMS has significant experience in the aerospace industry, having 3D scanned over 60 different aircraft for various organizations.

Aerospace 3D Scanning & Modeling Applications

- Complete aircraft

- Individual parts & assemblies

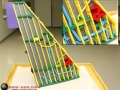

- Tooling & fixtures

- Interior layout & refurbishment

- Design validation

- Assembly inspection

- Replica parts for simulators