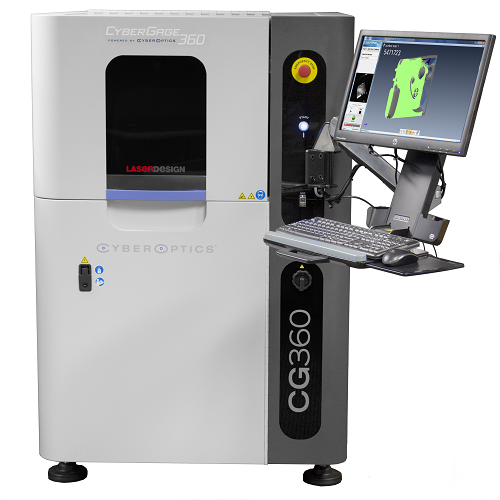

CyberGage360™ 3D Scanning System Overview

The new CyberGage360 from CyberOptics offers an unprecedented combination of speed, accuracy and one-button simplicity for non-contact automated 3D scanning inspection.The CyberGage360:

- Significantly speeds up quality assurance of in-process inspection and/or incoming-outgoing parts inspection

- Lowers cost of quality

- Speeds up product time-to-market

Designed for use in general purpose metrology, the CyberGage360 has a range of applications from medical to automotive to aerospace to consumer electronics, where high accuracy and high speed throughput are important.

High-Precision accuracy with Multiple Reflection Suppression (MRS) Sensor Technology

Easy-to-use Software with Push-Button Automation

Automated 3D Volumetric Part Scan and Inspection Report in less than 3 minutes

High-Precision accuracy with Multiple Reflection Suppression (MRS) Sensor Technology

- Generates an automated, highly precise, full 360⁰ volumetric scan with NIST traceable accuracy to 7 µm + L/10000.

- Incorporates CyberOptics’ proprietary 3D Multi-Reflection Suppression (MRS) technology that enables metrology-grade accuracy by inhibiting optical measurement distortion and reflections.

Easy-to-use Software with Push-Button Automation

- Simplifies scanning with one-button simplicity

- Provides factory-friendly operation with minimal training

- Generates automated inspection reports including a comparison of scan data to CAD models or models based on ‘golden’ examples.

- Programs off-line with pre-defined inspection templates

- Speeds part program selection with Bar Code Part ID

- Eliminates inspection gages with fixtureless design

- Offers quick and simple field recalibration

Automated 3D Volumetric Part Scan and Inspection Report in less than 3 minutes

- Quickly generates a highly precise, full 360⁰ volumetric 3D surface scan of complex shaped parts in <3 minutes

- Facilitates near-production line high-volume scanning and high speed throughput

FeaturesBenefitsImagesVideos

- Work Volume: 200mm diameter x 100mm high cylinder (8” diameter x 4” high)

- Sensor Technology: Patented MRS technology with structured blue light

- System Volumetric Accuracy: 7 µm; 0.007mm +L/10000mm (ISO 10360) See Accuracy Statement for CyberGage360 report available at CyberOptics.com/CyberGage360

- Repeatability: 5 µm; 0.005mm/0.00020” See Accuracy Statement for CyberGage360 report available at CyberOptics.com/CyberGage360

- Speed: Up to 16 million points/part/ pose. Typical cycle time < 3 minutes

- CDRH Safety: Eye safe - no protection needed

- System Controllers Embedded: High-performance PC included

- Environmental Temperature: Temperature ambient = 20°C +/- 3°C (68.5°F +/- 5°F) to maintain calibrated performance

- Operating Environment: Humidity 50% +/- 30%

- Weight of Part: 2.0 kg max (4.4 lbs.)

- Data Output Formats: STL, PLY, OBJ, ASC

- Electrical Requirements: 100-240 VAC, 3.6/1.8 Amps, 60-50Hz, Phase 1

- Included with System: PC controller built in, Polyworks Inspector inspection reporting software with: 1 year maintenance/updates/support, operation manual, maintenance manual, and training at factory

- Warranty: 1-year warranty (hardware, software, parts, labor, workmanship)

High-Precision Accuracy with MRS Technology

Easy-to-Use with One-Button Simplicity

Fast Scanning in Less than 3 Minutes

- Generates full 360° automated scan with accuracy to 7µm, 0.007mm +L/10000mm

- Incorporates CyberOptics’ proprietary 3D Multi-Reflection Suppression (MRS) technology that inhibits measurement distortions for a highly accurate metrology grade scan

Easy-to-Use with One-Button Simplicity

- Simplifies scanning with one-button automation

- Provides factory-friendly operation with minimal training

- Generates reports comparing scan data to CAD models or ‘golden’ example

- Speeds part program selection with Bar Code Part ID

- Programs off-line with pre-defined inspection templates

- Eliminates costly inspection gages with fixtureless design

- Offers quick and simple field recalibration

Fast Scanning in Less than 3 Minutes

- Quickly generates a highly precise full 360° automated 3D surface scanof complex shaped parts in less than 3 minutes

- Facilitates near-production line high-volume scanning and high speed throughput