Industrial CT Scanning

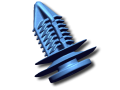

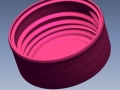

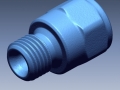

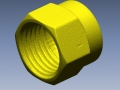

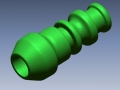

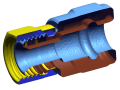

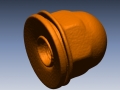

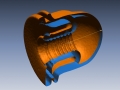

Industrial CT Scanning involves an X-Ray inspection machine capable of 3D scanning completely through a part or an assembly of parts. Materials including plastics, ceramics and composite materials, as well alloys such as aluminum and steel and other metals can also be CT scanned. This technology allows you to view imperfections inside a part such as cracks, voids, interferences and more.Benefits of Industrial CT Scanning

- 3D scan completely through a part or an assembly of parts

- Find cracks, voids, interferences and improper mating conditions

- 3D scan 100% of a part including small holes, and details

- Very high accuracy up to 8 microns (.08mm / .0003”)

- Can be used for reverse engineering or inspection

Industrial CT Scanning Deliverables

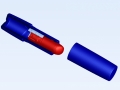

- Polygon models – STL

- 3D Surface model –IGES, STEP

- Feature based solid model & assemblies – IGES, STEP, ParaSolid, SolidWorks

- Hybrid CAD model (surfaces and solids) – IGES, STEP, ParaSolid, SolidWorks

- Customized inspection reports to include:

- Quick “go” or “no go” reports

- Dimensions & measurements

- Colormaps indicating tolerance, curvature, deviation & more

- GD&T & 3D GD&T

- Sectional views with measurements and deviation

- Min, max, average & standard deviation

- Output PDF, PPT, Excel and other formats

Request a 3D Scanning Services Custom Quote

ImagesSuccess Stories